About the project

Skateboarding is a huge market (~$15bn) that has been experiencing increased interest and sales during the last years. There are many factors that add up to these trends, including the various competitions held such as Street League and X Games that have promoted the sport, as well as the inclusion of skateboarding in the 2020 Summer Olympics (held from 23 July to 8 August 2021 in Tokyo, Japan). In addition, skateboard manufacturers now follow effective and tailored-made marketing tactics to popularize their brands as a symbol on skateboards, a strategy that has attracted new consumers, particularly teenagers, due to their preference towards funky and attractive graphics.

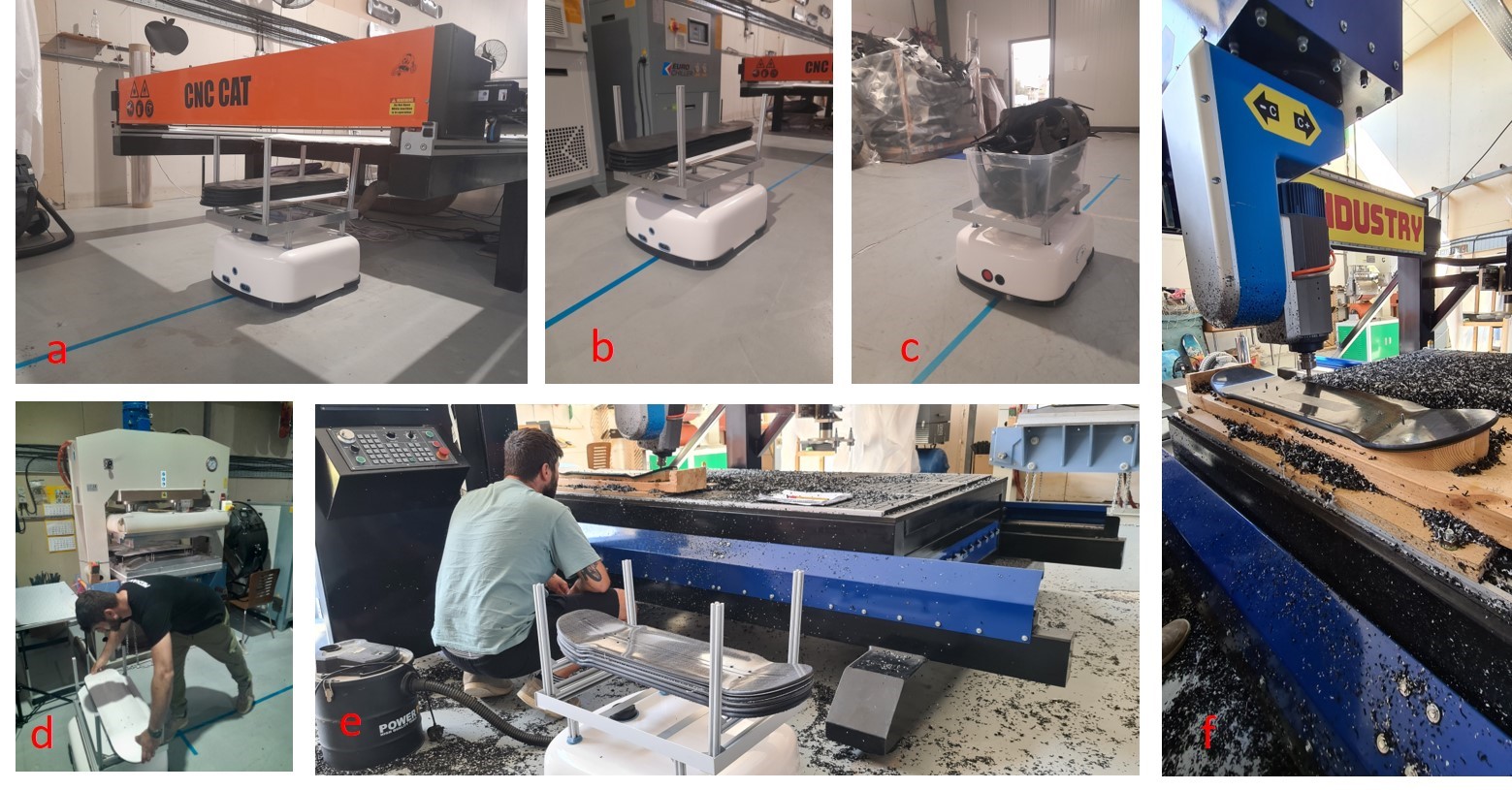

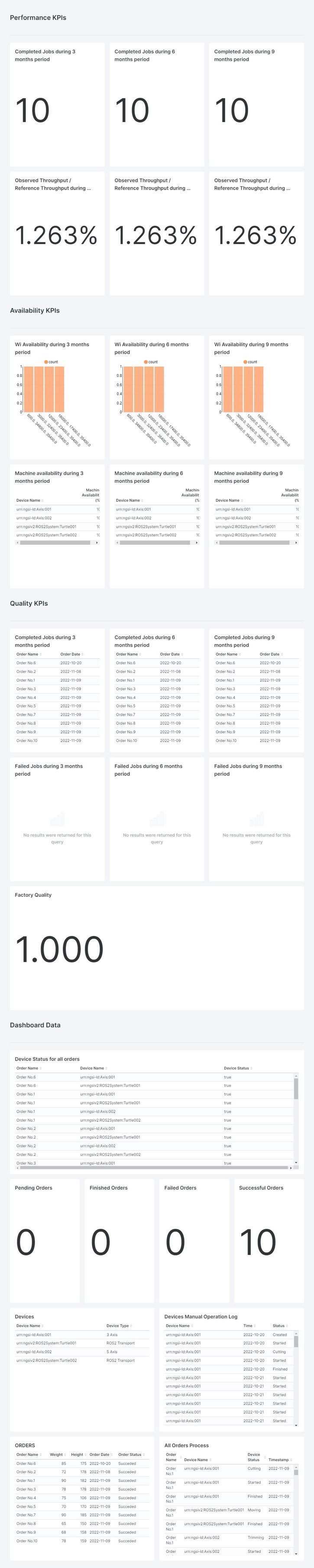

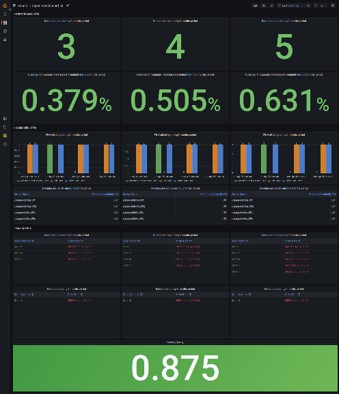

Through the COBBIT-DIH2 project we aim to completely shift to a dynamic and agile manufacturing process, supported by FIWARE, digital, and robotized infrastructure. What needs to be further integrated in our current production line is a fully automated and agile process consisting of Two Transportation Robotic Platforms (a primary and a secondary), one custom-made combined 3 axis cartesian robotic laser cutter and one customised 4 axis cartesian robotic laser cutter/router.

Sustainable Development Goals:

People:

-

Iasonas Iasonos - Senior Software Developer - Developer

-

Christoforos Kronis - Senior Software Developer - Developer

-

Andreas Konstantinidis - Director - Principal Investigator

Image Gallery:

.png)